Description

Leather Hide Welder’s Glove / Aluminised Back

A thermal aluminized leather glove protects against extreme heat and is ideal for work in heavy industry.

₱3,769.00

Product images are for illustrative purposes only and may differ from the actual product.

Click here to view the Size Guide

Aluminised Kevlar® Preox

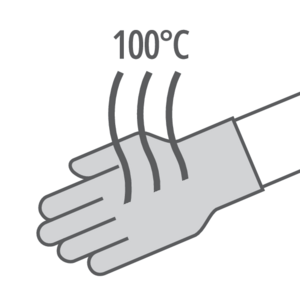

High thermal resistance to radiant heat

THT treated heat resistant leather

Decreased responsiveness to flames

Increased resistance to contact heat due to its treatment

High flexibility of the leather

Exceptional thermal results, a constant quality unmatched in its field thanks to the aluminized Preox made in France.

Performance

Extra thick and long for extra protection of the entire arm

THT-treated heat-resistant leather provides increased resistance to contact heat

Resistant to flame, heat, and large splashes of molten metal, ideal for welding and heat protection applications

EN388:2016 Protective gloves against mechanical Risks (Levels obtained on the palm)

| 3 | Resistance to abrasion (from 1 to 4) | |

| 2 | Resistance to cutting (from 1 to 5) | |

| 4 | Resistance to tear (from 1 to 4) | |

| 4 | Resistance to puncture (1 to 4) | |

| X | Resistance to cutting by sharp objects (TDM EN ISO 13997) (from A to F) |

EN12477:2001/A1:2005 Protective gloves for welders

| TYPE | A | Welding – Other welding processes – less dexterity – Type A |

A thermal aluminized leather glove protects against extreme heat and is ideal for work in heavy industry.

| Size | |

|---|---|

| Color | Orange-Grey |